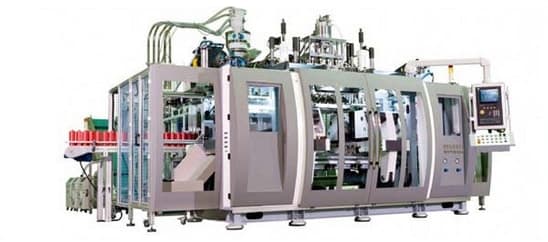

Purging your blow molding machine is necessary to ensure optimal performance and a superior end product. While there are some differences between standard and custom blow molders, the blow molding design is similar enough that there is no real impact on the purging process. Even when it comes to extrusion blow molding vs. injection blow molding, purging is essential.

Safety First

If you plan to purge standard or custom blow molders, safety is the number 1 priority. Therefore, be sure that you follow all required safety procedures before the startup and shutdown, regardless of the material. You need to don the appropriate protective clothing, gloves, and eye-wear, and use a shield. If the machine has a vented barrel, clean the area around the plug and vent before sealing.

Read more at the original source.

Contact Details:

PET ALL MANUFACTURING INC.

85 Royal Crest Court, Units 1 & 2 Markham,

Ontario, L3R 9X5

Phone: (905) 305-1797

Email: cmerrick@petallmfg.com