Although stretch blow molding produces a variety of products, it is best known for the production of PET bottles used for juices, sports drinks, water, and similar products. First introduced in the early part of the 1970s thanks to advanced materials and techniques, it is now what manufactures prefer among the different types of blow molding for making bottles for carbonated beverages.

The primary benefit of using this molding process is that it can stretch a preform in both the axial and hoop direction. With the biaxial stretching of materials, tensile strength increases, as does clarity, drop impact, barrier properties, and top load. Also, the weight of the container decreases by as much as 15 percent compared to using one of the other types of blow molding processes.

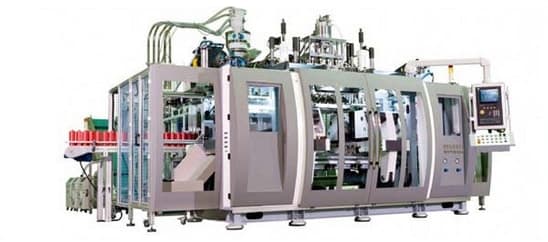

There are two categories: single-stage and two-stage. For the single-stage, an extruder injects a parison into the preform mold where the plastic material cools rapidly to form the preform. Once reheated and placed into the bottle mold, the now-softened parison stretches to roughly 50 percent of its original length. At that point, compressed air gets blown into the parison, expanding it to the bottle mold. After the bottle cools, the mold opens and the finished product ejects.

Read full post at the original source: http://www.petallmfg.com/blog/stretch-blow-molding-and-its-various-uses/

Contact Details:

PET ALL MANUFACTURING INC.

85 Royal Crest Court, Units 1 & 2 Markham,

Ontario, L3R 9X5

Phone: (905) 305-1797

Email: cmerrick@petallmfg.com

.